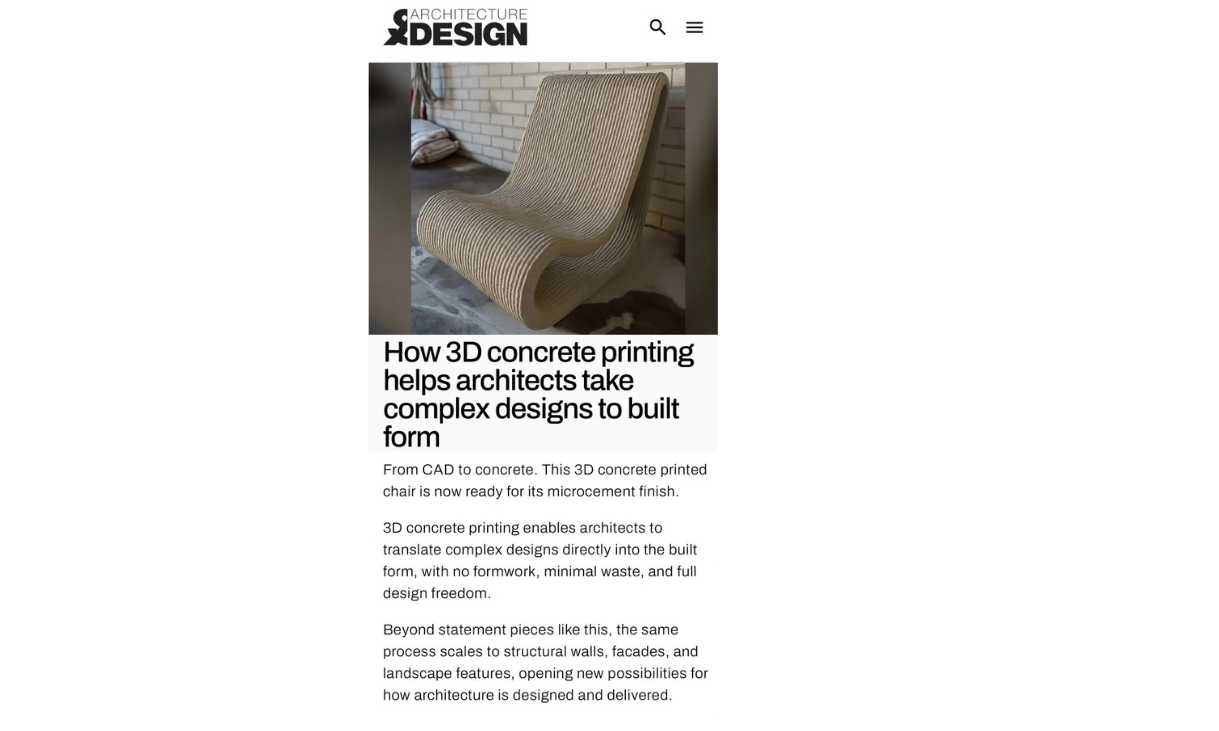

Digital Design: The process begins with a digital 3D model of the structure, created using computer-aided design (CAD) software. This model provides the precise specifications for the printer to follow.

Concrete Mixture: A specialised concrete mix is prepared. This mix is often tailored to be flowable enough to be extruded through the printer nozzle yet quick-setting to support subsequent layers without deformation.

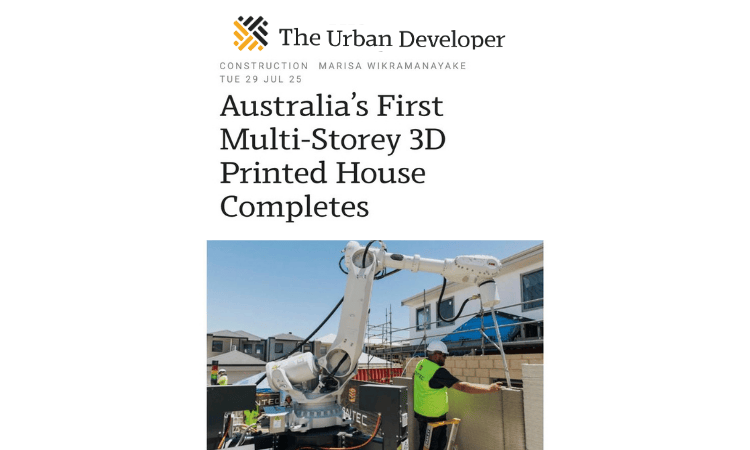

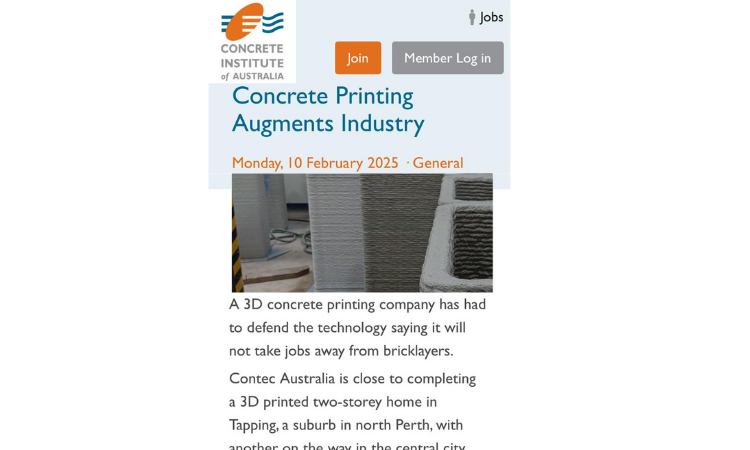

Printing Process: The Contec 3D printers large robotic arm follows the digital model’s instructions to extrude the concrete layer by layer. The nozzle moves in precise patterns, depositing the concrete in successive layers to build up the structure.

Layering: Each layer is printed in a predefined sequence. The printer ensures that the layers bond together properly, resulting in a solid and cohesive structure.